News

Do you know what a medium efficiency bag filter is? What is its function? I believe most friends still don't understand these issues. But don't worry too much. Today's article mainly discusses where medium efficiency bag filters are mainly used? If you are also interested in this topic, then read on with the editor. I hope you will be able to provide some better help when selecting in the future.

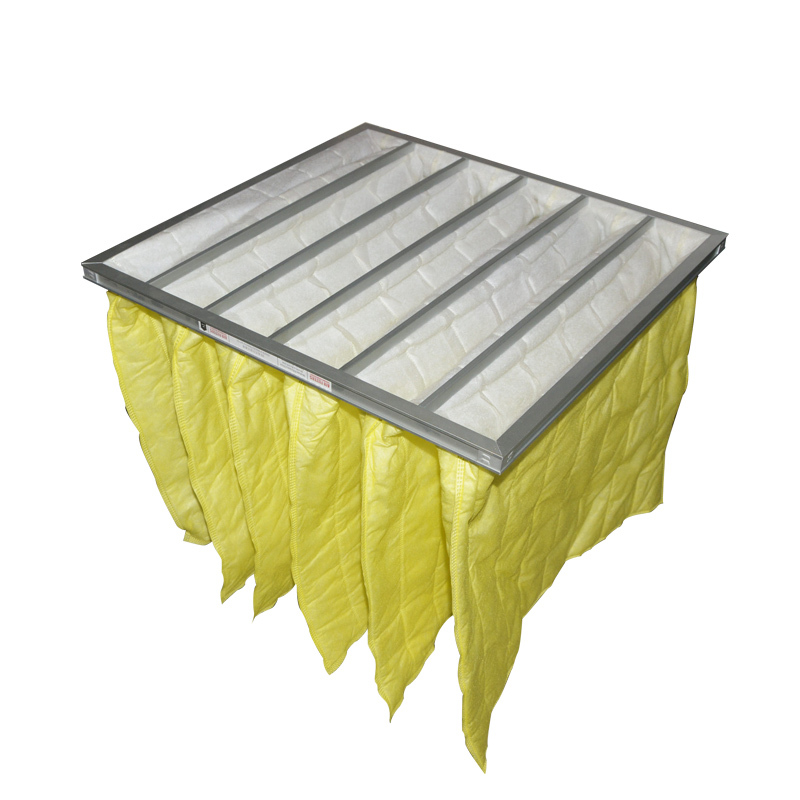

Nowadays, it is used in many industries, but most people still feel unfamiliar when they see it. Therefore, the first thing we need to know before using is the effectiveness of the medium efficiency bag filter, which is mainly used in central air conditioning and air supply systems. The intermediate filter can be used in air conditioning systems, and the middle and lower filters do not have strict requirements for the cleanliness of clean air to protect the system and the system itself. Therefore, the air that has been effectively filtered can be directly delivered to users. Its framework includes forms such as cold plate spraying and galvanized sheet, and filter materials such as non-woven fabric and fiberglass. In fact, this product is widely used in industrial purification such as central air conditioning ventilation systems, pharmaceuticals, hospitals, electronics, and food. It can also serve as a front-end filter for HEPA filters, reducing the load on HEPA filters and extending their service life. Due to its large windward side, the bag filter has a high suction capacity and low wind speed, and is considered to be the current medium efficiency filtration structure. In fact, the medium efficiency bag filter is mainly based on its unique bag structure, which ensures the airflow balance of the entire bag. In addition, it has a unique hot melt technology that prevents excessive squeezing or leakage between bags, reduces resistance, and maximizes dust capacity. The strengthened 'bag support grille' prevents the filter from shrinking or bending under harsh working conditions.

Of course, medium efficiency bag filters can be used as ideal medium efficiency filters in humid, high airflow, and high dust load environments. After the bag filter was launched, it was applied in the pharmaceutical, automotive and food manufacturing industries, commercial buildings, as well as various industrial and ventilation systems. Through this approach, it has successfully demonstrated their value and performance, raising industry standards. In fact, medium efficiency bag filters can withstand significant working pressure during operation. Compared with ordinary filters, it has stronger strength, so the pressure loss of the equipment is small, the operating cost is relatively low, and the energy-saving effect is very obvious, saving costs for the majority of users. Medium efficiency bag filters are very suitable for some small and medium-sized industrial enterprises, especially those that are just starting out. In addition, although the size of the equipment is limited, the number of devices is large, which can also reduce the number of cleaning times. In addition, medium efficiency bag filters can be cleaned every three months to six months and can be used for large equipment. As the flagship product of our factory, we would like to thank our new and old customers for their strong support. While ensuring the reliability of product quality, we also benefit our customers. If you have any technical questions about the product, you can always come here for consultation.

The above article is about the main applications of medium efficiency bag filters for friends. If you have any needs in this area, you can check it out. I hope it can be helpful to you.