News

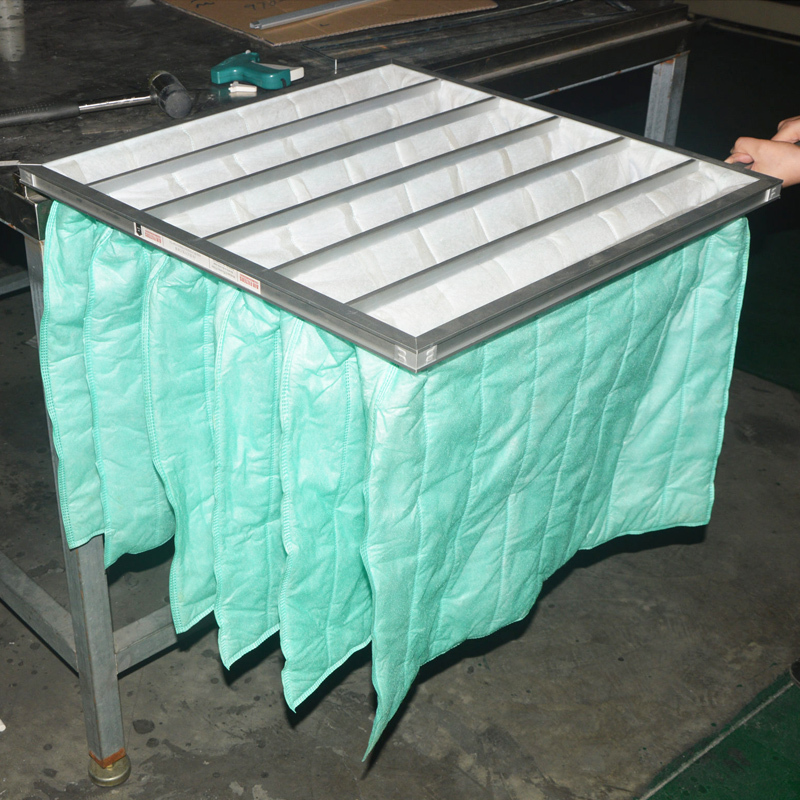

The initial efficiency plate filter is a common type of air filter, often made of artificial fiber filters. It uses a sturdy and moisture-proof hard paper frame as the outer frame, which is not deformed, broken or twisted under normal operating conditions. The filter is fixed diagonally in front and behind the outer frame to ensure tight contact between the filter and the outer frame, preventing air leakage. Widely applicable, such as air conditioning and ventilation systems for primary filtration of clean room return air, pre filtration as a locally effective filtration device, mainly for primary filtration in multi-stage filtration systems. So, let's learn together how the efficiency of primary efficiency plate filters is measured!

The primary efficiency plate filter is mainly used for calculating the filtration efficiency of dust particles with a particle size of 5m or more. Filter materials include non-woven fabric, nylon mesh, aluminum mesh, stainless steel mesh, etc. Polish the air outlet surface of non-woven filter materials to prevent secondary pollution caused by non-woven fiber breakage and scattering. Next, we will discuss the calculation method. The calculation method is generally used to measure the low efficiency filter used as a pre filter in air conditioning systems, namely the initial effect filter.

The filtration efficiency of a primary plate filter is the ratio of the amount of dust captured to the original air dust content. The filtering efficiency of the initial filter is the value obtained by subtracting the ratio of downstream air dust content to upstream air dust content. The filter is set in the standard test wind tunnel and intermittently reduces dust at the upper end of the wind. The weight of dust passing through the filter (the amount of dust collected on the filter) is measured at regular intervals. The filter is set in the standard test wind tunnel and intermittently reduces dust at the upper end of the wind.

Measure the weight of dust passing through the filter (the amount of dust collected on the filter) at regular intervals, in order to obtain the filtration efficiency calculated by the filter based on the weight of dust at that stage. Measurement efficiency is the weighted average of the corresponding dust volume for each experimental stage. At the end of the experiment, the weight of the filter containing the test dust is called the "dust holding capacity". The final test conditions for metrological testing are valid based on the resistance value agreed upon with the customer, or the resistance value specified by the tester themselves, or efficiency.

It should be noted that the metering method test for initial plate filters is a destructive test and cannot be used for the performance polishing of manufacturers' daily products.

The initial efficiency plate filter has been increasingly recognized by more and more people, improving air quality and ensuring people's health, and has been widely used. For example, industries such as medicine and food cannot do without filters with various efficiencies. I believe that in the future, filter manufacturers will continue to innovate and provide better services to people.

The above introduction is how the efficiency of the initial plate filter is measured. If you need to know more, please feel free to contact us at any time!